1. The cost of this air current dryer is much lower than rotary dryer.

2. sawdust rotary dryer is professionally designed for the drying of different kinds of wood sawdust.

3. sawdust rotary dryer is character with low cost, low consumption, high capacity, easy operation and maintenance and so on.

4. In addition, the round places of pipes can be changed to any angle which can save space and solve dimension limitation of plant.

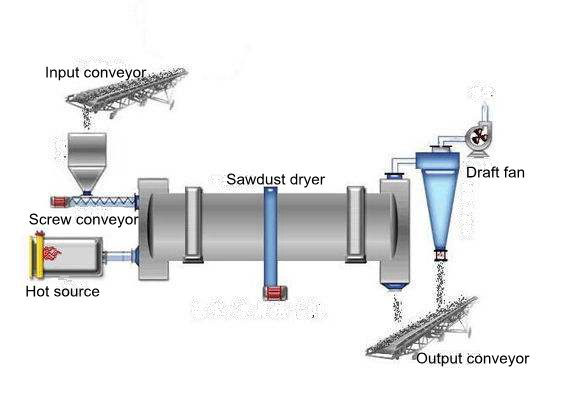

Working principle of sawdust dryer

After being sent to the dryer chamber, the wood material will be handled by both the spray torch and the rotary cylinder. Then the wood material gets separated and fluidized inside the chamber, allowing the hot stream to be fully contacted with the wood.

The air flow type sawdust dryer is used for drying of wet partical/powdered sawdust. The screw conveyor can continuously feed the wet sawdust into the drying tube. The sawdust isseparated in high-speed heat flow, and the moisture in the sawdust will be evaporated quickly and obtain the dried and powdered sawdust.

Customer Service

If ore sample is provided by customers, we may do free spectrum or other testing. The testing reported is conducted by Mineral Prospecting Institute, and ranks the top in China.

According to requirements for final products, we may provide free reagent ratio and dosage to customers.

After knowing detailed information from customers, our technicians will provide the workflow and configuration for free.

Our technicians will provide local design, layout, and tailing design for free after knowing detailed area of customers.

Our engineer may provide 10 day’s training and guidance for free if necessary (including operation of machines, working notes and maintenance).