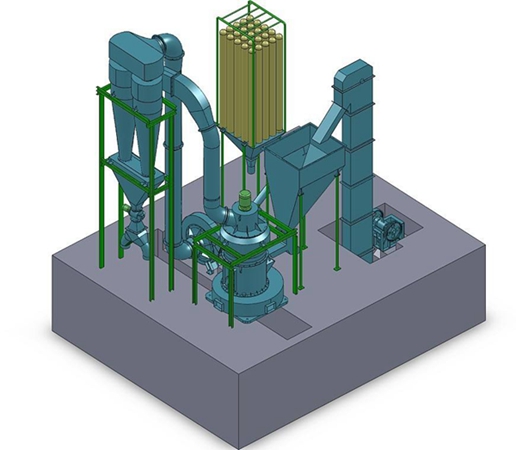

Overview of High pressure grinding mill

The complete name of High pressure grinding mill is high pressure suspension grinding mill, which is a new type grinding mill used in grinding the stone into micro powder. Powder grinding mill can be used for processing some materials such as limestone, calcite, marble and kaolin with Moh’s hardness less than 6 degree.

High pressure grinding mill has wider application than the jet mill. Compared with other similar products, this machine adapts higher pressure spiral, which can help increase the pressure, and the output of every device is much higher than before.

The material can be grinded to below 6.5um by one time grinding, so this machine is also called micro powder grinding mill.

The high pressure grinding mill is mainly used for grinding processing of metallurgy, building materials, chemic, mining and other mineral material, powder millstone, feldspar, calcite, talc, barite, fluorite, rare earth, marble, ceramic, aluminum vanadium and soil, manganese ore, iron ore, copper, phosphate ore, red iron oxide, zircon sand, slag, water slag, cement clinker, activated carbon, dolomite, granite, garnet, yellow iron oxide, bean cake, fertilizer and compound fertilizer, fly ash, bituminous coal, coking coal and lignite, diamond beautiful sand, green chrome oxide, gold, red mud, clay, kaolin, coke, coal gangue, China clay, fluorite, medical stone, synthesizing, shale, violet stone, green muddy rock, build up rocks, basalt stone, plaster, graphite, silicon carbide and other kind of inflammable and explosive mineral materials with Moh’s hardness less than 9.3 degree and humidity less than 6%.

Working principle of High pressure grinding mill

General: Crushing -- Grinding -- Selecting -- CollectingDetail: The High-pressure Suspension Mill has the same working principle as Raymond Mill, but its grinding fitting is equipped with 1, 000 – 1, 500 kg pressure spring.

When the machine works, the grinding roll closes grinding ring under the action of high pressure spring and centrifugal force. Its rolling pressure ratio is 1.2 times of Raymond mill given in an identical condition, and its output may increase by 10% to 20%. Please note that when the grinding roller and grinding ring reach a certain degree of abrasion, please adjust the length of high-pressure spring to keep the constant grinding pressure between grinding roller and grinding ring in order to ensure a stable output and fineness.

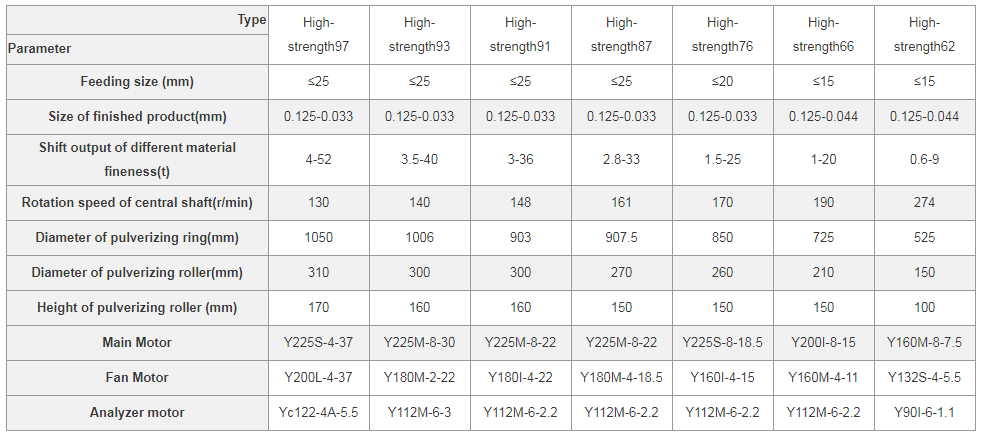

Technical data of high pressure grinding machine

Customer Service

Testing

If ore sample is provided by customers, we may do free spectrum or other testing. The testing reported is conducted by Mineral Prospecting Institute, and ranks the top in China.

Reagent Recipe

According to requirements for final products, we may provide free reagent ratio and dosage to customers.

Workflow

After knowing detailed information from customers, our technicians will provide the workflow and configuration for free.

Local Design

Our technicians will provide local design, layout, and tailing design for free after knowing detailed area of customers.

Guidance

Our engineer may provide 10 day’s training and guidance for free if necessary (including operation of machines, working notes and maintenance).