Rotary dryer, also known as rotary drum dryer,rotary drier.

According to different ways of heating raw material,the rotary dryer can be divided into direct heating-type rotary dryer and indirect heating-type rotary dryer. The rotary dryer can be classified into Coal Slime Rotary Dryer , Coconut shell dryer, slag rotary dryer and clay rotary dryer according to different raw materials. According to different structure, the rotary dryer can be divided into Three cylinder dryer , Double-drum Dryer.

Being widely used in building materials, metallurgy, chemicals, industrial drying slag cement limestone, coal, slag, clay and other materials.

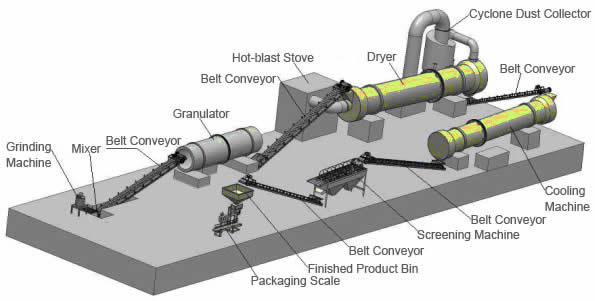

The aircraft is mainly composed of the rotary, jan plate, transmission, seals, and other support equipment and components.

Being featured with a reasonable structure, well-produced, high yield, low consumption and operating convenience.

Offering products quality assurance, and highest free installation debugging agent can be checked with other plants than quality and prices.

When rotary Dryer is operating, it shall be in direct contact with heated gas. The dryer consists of a large rotating cylindrical tube. In order to convey the material through the underside of dryer, the dryer should be slanted slightly to ensure that the discharge end is lower than the end of material feed .

Working Principle of Rotary Dryer: Material shall be dried to enter the dryer. When the dryer is rotating, a series of internal fins will lift the material by lining the inner wall of the dryer. When the material reaches certain height to roll the fins back, it will be fell back to the bottom of the dryer, then passing through the hot gas stream as it falls. This gas stream can either move toward the discharge end from the feed end (known as co-current flow), or toward the feed end from the discharge end (known as counter-current flow). The gas stream can be composed of a mixture of air and combustion gases from a burner, and in which case the dryer is known as a direct heated dryer. Alternatively, the gas stream may be made up of air or another (sometimes inert) gas that is preheated. When the gas stream is preheated by some means where burner combustion gases are not permitted to enter the dryer, the dryer shall be called an indirect-heated type. Indirect heated dryers are commonly used when product contamination becomes a concern.

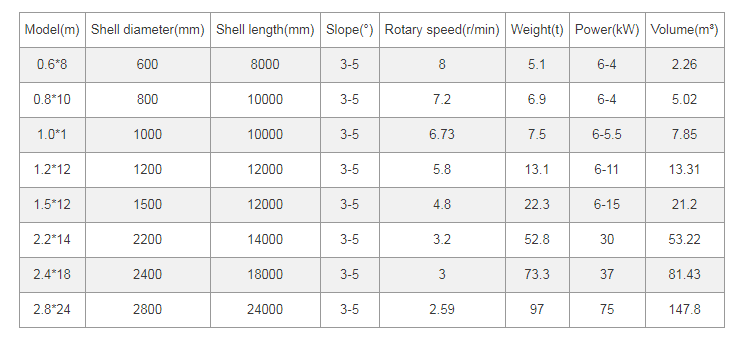

Technical data of rotary dryer

If ore sample is provided by customers, we may do free spectrum or other testing. The testing reported is conducted by Mineral Prospecting Institute, and ranks the top in China.

According to requirements for final products, we may provide free reagent ratio and dosage to customers.

After knowing detailed information from customers, our technicians will provide the workflow and configuration for free.

Our technicians will provide local design, layout, and tailing design for free after knowing detailed area of customers.

Our engineer may provide 10 day’s training and guidance for free if necessary (including operation of machines, working notes and maintenance).