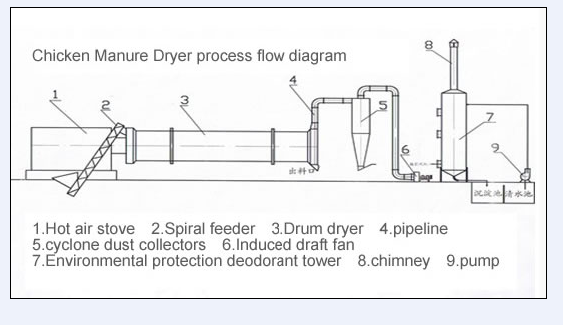

Chicken manure drying machine mainly consists of heating source, feeder (CJAL), feeding machine, rotary roller, material crushing devices, discharging machine, induced draft fan, discharger and power distribution cabinet; After dehydrated, wet materials into the drying machine, the shoveling plate which, the material equably dispersed inside the drying machine and fully contact with hot air, speeding up the drying heat transfer and mass transfer. In drying process, materials in the function of in a gradient shoveling plate with hot, finished products are discharged from another section valve of the dry machine.

Drying capacity | 500-800kg/h | 1000-1500kg/h | 1500-1800kg/h | ≥2500kg/h |

Rotation speed and power | 3-4rmp,4kw | 3-4rmp,5.5kw | 3-4rmp,10kw | 3-4rmp,15.5kw |

Crushing spindle | 150-250rmp,3kw | 150-250rmp,4kw | 150-250rmp,4kw | 150-250rmp,5.5kw |

Draught fan power | 7.5kw | 11kw | 15kw | 18.5kw |

Coal consumption | ≤70kg/h | ≤110kg/h | ≤170kg/h | ≤220kg/h |

Floor area | ≥80m2 | ≥100m2 | ≥120m2 | ≥150m2 |

Dryer weight | 4T | 6T | 12T | 19T |

If ore sample is provided by customers, we may do free spectrum or other testing. The testing reported is conducted by Mineral Prospecting Institute, and ranks the top in China.

According to requirements for final products, we may provide free reagent ratio and dosage to customers.

After knowing detailed information from customers, our technicians will provide the workflow and configuration for free.

Our technicians will provide local design, layout, and tailing design for free after knowing detailed area of customers.

Our engineer may provide 10 day’s training and guidance for free if necessary (including operation of machines, working notes and maintenance).