Dung dryer is widely used for drying materials in the industries of cement, mine, construction, chemical, food, compound fertilizer, etc. Feeding and discharging unit is installed with thermocouple to control drier temperature. The temperature change of drier’s feeding end can be indicated by the thermometer to control the inner drier temperature (generally 250-350°C).

Cow dung dryer is made up of Stove, main rotary body, screw conveyor, cyclone separator, air-lock, and fan and matched pipes which can realize to reduce the moisture from 60% to10%. Mainly used in building material, metallurgy, chemical plant, cement plant for drying of limestone slag, coal powder, slag, and clay stone, the dung dryer has advantages of reasonable structure, high efficiency, low energy consumption and convenient for transportation.

Features of manure dung dryer

The internal dung dryer adopts assembled structure which has improved the accuracy of equipment and it is easy to transport and install.

According to the characteristics of different fertilizers, we have arranged the second granulation zone reasonably so as to improve the granulation effect.

Assembled hoist board is adopted to exchange heat fully and lower the energy consumption.

Temperature induction monitor, uniform vibration and airproof setting, which can improve performance and productivity efficiently.

The assorted combustion furnace has the characteristics of smaller area, easy regulation and equipped with greenhouse.

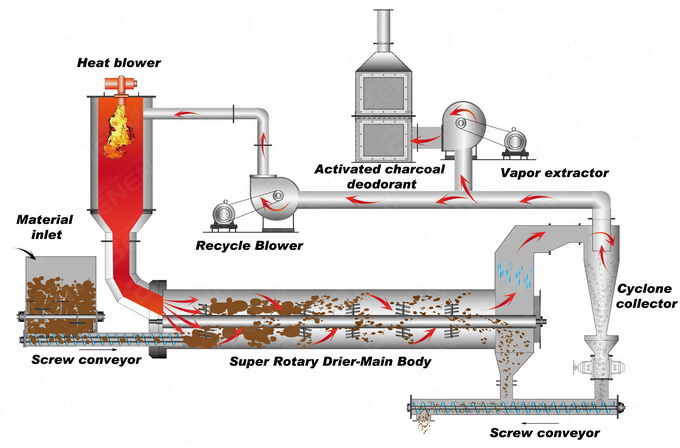

Working principle of manure dung dryer

Cow dung dryer adopts direct flow type of heating with heat source from firing unit. The material to be dried is pushed back immediately by spiral board when enters the shell from feeding tank and feeding chute. Because the drier is installed in slope, material flows to the back end under gravity and rotation force. Meanwhile, it is lifted by board repeatedly and thrown down accordingly, which make the material form even curtain, and exchange heat sufficiently with inner the heat flow. In the end, water in the material is dried by repeatedly scattering.

Structure of cow dung dryer:

Cow dung dryer is mainly composed of shell, back and forth supporting wheel, feeding and discharging unit and gear cap. The accessories which are not in the scope of this machine include firebox, feeding and discharging equipment, dust catcher, etc.

Customer Service

Testing

If ore sample is provided by customers, we may do free spectrum or other testing. The testing reported is conducted by Mineral Prospecting Institute, and ranks the top in China.

Reagent Recipe

According to requirements for final products, we may provide free reagent ratio and dosage to customers.

Workflow

After knowing detailed information from customers, our technicians will provide the workflow and configuration for free.

Local Design

Our technicians will provide local design, layout, and tailing design for free after knowing detailed area of customers.

Guidance

Our engineer may provide 10 day’s training and guidance for free if necessary (including operation of machines, working notes and maintenance).