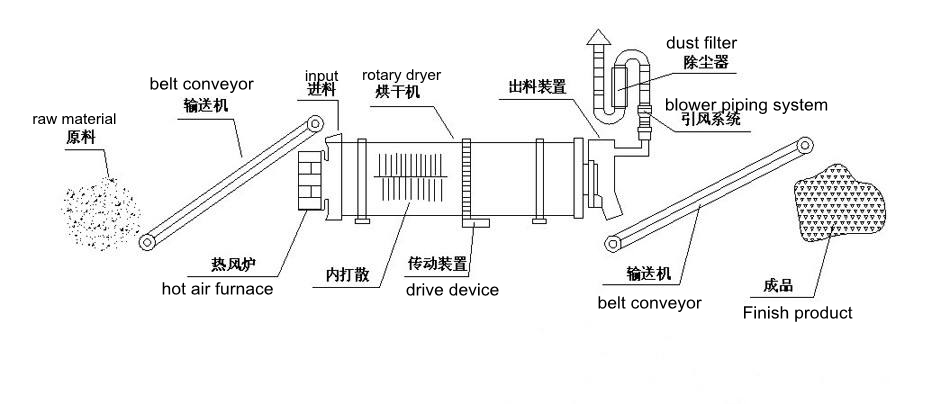

Coconut shell dryer consists of heating furnace, feeding mouth, rotating tube, filter tube, material conveying tube, cooling tube and discharge mouth.

Rotating tube is located on the active wheel. The rotary barrel is moved by active wheel in low speed by using the motor and deceleration drive. There is feeding mouth between the heating furnace and rotary barrel, and there are stirring blades inside the rotary barrel, a baffle between the rotary barrel and the filter tube and a hole on the baffle.

It is connected with rotary barrel on one side of the filter tube and the other end is connected with material conveying tube. There is block inside the filter tube and a slag discharge hole at the bottom of the filter tube. One side of the cooling tube is connected with material conveying machine by the air blower and the other end of the cooling tube is connected with the discharge mouth.

The waste coconut shell can be fully dried in rotating cylinder by using the structure, and coconut shell waste can fully spread again before going into the material conveying pipe to make moisture evaporate quickly. The block can block the impurities in waste coconut shell to ensure quality of coconut waste which enters the material conveying pipe.

When coconut shell waste enters into the dryer, it is processed by interaction of injection tube and rotating cylinder. The material is boiled and fluidified in the tube, and the material can fully access to the hot blast to complete drying.

| Model | The Diameter (mm) | The Length (m) | Slope(°) | Speed (r/min) | Power (kw) | Volume (m3) |

| 0.6×8-12 | 600 | 8-12 | 3-5 | 8 | 4 | 2.26 |

| 0.8×10-10 | 800 | 10-12 | 3-5 | 7.2 | 4 | 5.02 |

| 1.0×10-12 | 1000 | 10-12 | 3-5 | 6.73 | 5.5 | 7.85 |

| 1.2×12-18 | 1200 | 12-18 | 3-5 | 5.8 | 11-15 | 13.31 |

| 1.5×12-18 | 1500 | 12-18 | 3-5 | 4.8 | 15-22 | 21.2 |

| 1.8×12-18 | 1800 | 12-18 | 3-5 | 3.2 | 185-30 | 48.22 |

| 2.2×12-22 | 2200 | 12-22 | 3-5 | 3 | 22-30 | 70.43 |

| 2.8×15-24 | 2800 | 15-24 | 3-5 | 2.59 | 30-55 | 147.8 |

If ore sample is provided by customers, we may do free spectrum or other testing. The testing reported is conducted by Mineral Prospecting Institute, and ranks the top in China.

According to requirements for final products, we may provide free reagent ratio and dosage to customers.

After knowing detailed information from customers, our technicians will provide the workflow and configuration for free.

Our technicians will provide local design, layout, and tailing design for free after knowing detailed area of customers.

Our engineer may provide 10 day’s training and guidance for free if necessary (including operation of machines, working notes and maintenance).