Features of ball mill

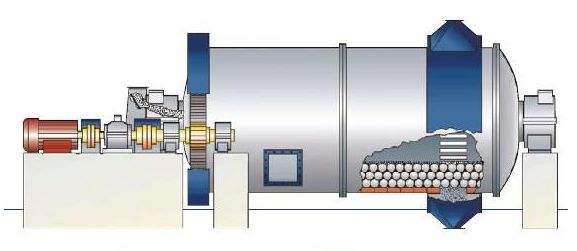

Ball mill is mainly made up of feeding part, discharging part, rotary part and driving part, including reducer, small drive gear, electrical machine and electronic control. The hollow shaft adopts steel casting, and its inner lining is detachable and changeable while the rotary rack wheel uses casting gear hobbing and there is a wear-resisting lining board inside the cylinder with good abrasion performance. This machine is featured with stable operation and reliable performance.

Working principle of ball mill

This machine is a horizontal cylinder rotating device. It is equipped with drive gear which drives the cylinder for rotation in the working process outside the cylinder. Materials go into the first cabin of the Grinding machine spirally and evenly through the feeding hollow shaft from the feeding device, and there are ladder lining boards or ripple lining board inside the first cabin where there are different kinds of steel balls. When the cylinder rotates and produces eccentric force to bring the steel balls to a certain height, the steel balls will fall down to impact and grind the materials. After being coarsely grinded in the first cabin, the materials will go into the secondary cabin where there are flat lining boards through the single-layer partition board. There are steel balls for further grinding the materials in the lining board. Finally the powdery materials will be discharged from the discharging grating bar to complete the powder grinding process.

Technical data of Ball mill

Customer Service

Testing

If ore sample is provided by customers, we may do free spectrum or other testing. The testing reported is conducted by Mineral Prospecting Institute, and ranks the top in China.

Reagent Recipe

According to requirements for final products, we may provide free reagent ratio and dosage to customers.

Workflow

After knowing detailed information from customers, our technicians will provide the workflow and configuration for free.

Local Design

Our technicians will provide local design, layout, and tailing design for free after knowing detailed area of customers.

Guidance

Our engineer may provide 10 day’s training and guidance for free if necessary (including operation of machines, working notes and maintenance).