Working principle of Jaw Crusher

The crashing method of this crushing machine is dynamic extrusion. Its working principle is as follows: the electro motor drives the belt and belt wheel to make the movable jaw to move up and down through the eccentric shaft. When movable jaw goes up, the angle between the toggle pate and the movable jaw will be bigger so as to push the movable jaw to move toward the fixed jaw. The materials are crushed or smashed for realization of crushing at the same time. When the movable jaw goes down, the angle between the toggle pate and the movable jaw will be smaller, and the movable jaw will move away from the fixed jaw under the effect of the draw bar and the spring, and then the crushed materials will be discharged out from the lower mouth of the crushing chamber. With the continuous rotation of the electro motor, the movable jaw of the crusher will be crushed and discharged periodically motion to realize the purpose of mass production.

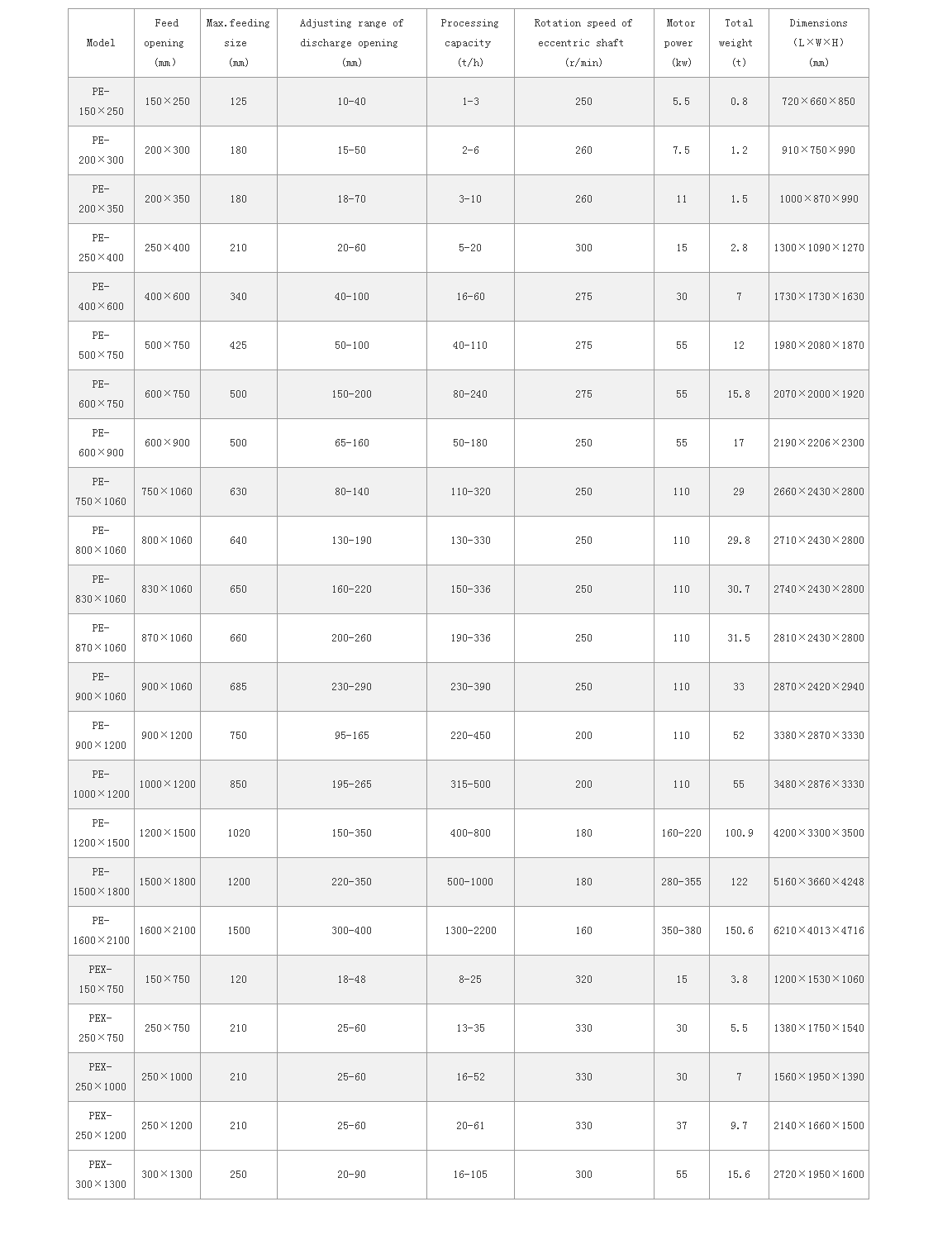

Technical data of Jaw Crusher

Customer Service

Testing

If ore sample is provided by customers, we may do free spectrum or other testing. The testing reported is conducted by Mineral Prospecting Institute, and ranks the top in China.

Reagent Recipe

According to requirements for final products, we may provide free reagent ratio and dosage to customers.

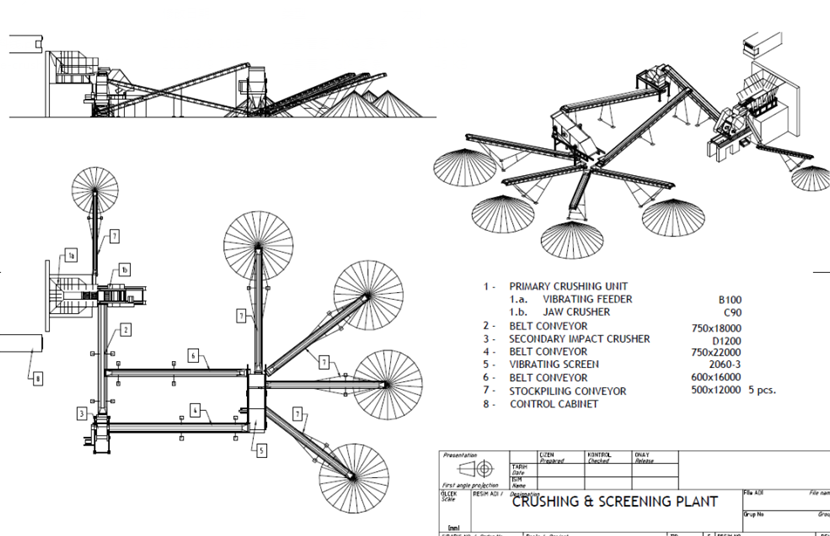

Workflow

After knowing detailed information from customers, our technicians will provide the workflow and configuration for free.

Local Design

Our technicians will provide local design, layout, and tailing design for free after knowing detailed area of customers.

Guidance

Our engineer may provide 10 day’s training and guidance for free if necessary (including operation of machines, working notes and maintenance).