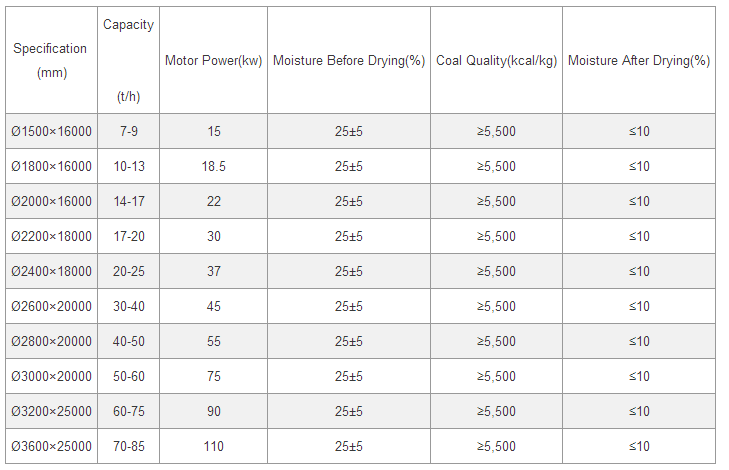

Large capacity, low fuel consumption, low drying costs;

High thermal efficiency: It adopts downstream drying. Both the heated gas and wet material enter the coal slime dryer from the same side, the high-temperature gas create strong evaporation and outlet temperature is comparatively low;

Operating parameters can be changed depending on the material properties, so that the material in the dryer cylinder body is capable of forming a stable full cut fabric curtain to get full heat exchange;

New feeding and discharging devices to solve the problem of feed clogging, not continuous, uniform and returning materials of the slime drum dryer reducing the load of dust removal system;

New internal structure, and strengthen the function of cleaning and thermal conductivity of the dispersed material, avoid material sticking on the cylinder wall;

It achieves "zero thrust" of this coal slime dryer, which greatly reducing wear of roller block, smooth and reliable operation;

Adopt "self-aligning roller-type device ", make roller and rolling ring linear touch forever, thus greatly reducing the wear and power loss;

The user can control the material particle size and moisture according to requirements, the finished slime moisture is less than 8%, and partical size can be controlled in 8mm.

Customer service

Testing

If ore sample is provided by customers, we may do free spectrum or other testing. The testing reported is conducted by Mineral Prospecting Institute, and ranks the top in China.

According to requirements for final products, we may provide free reagent ratio and dosage to customers.

After knowing detailed information from customers, our technicians will provide the workflow and configuration for free.

Our technicians will provide local design, layout, and tailing design for free after knowing detailed area of customers.

Our engineer may provide 10 day’s training and guidance for free if necessary (including operation of machines, working notes and maintenance).