Introduction of micro powder mill

Micro powder mill is designed according to our many years manufacturing experience, absorbing the Swedish advanced machine manufacturing techniques. It is a new type of mill for making super fine powder through more than 20 times of test and improvement. Under the same conditions, the production capacity and fineness is three times and 300 mesh higher than that of Raymond and medium-speed mill respectively, exceeding the fineness limit of wet stirred mill, which has been the first choice of high-tech, efficiency and energy- saving mill.

Micro Powder grinding mill is the equipment specializing in producing fine and superfine powder of non-inflammable, non-explosive and brittle materials such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite and vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alunite, graphite, fluorite, rockphosphate, Kalium ore, pumice, etc.,with Moh’s hardness below six levels.

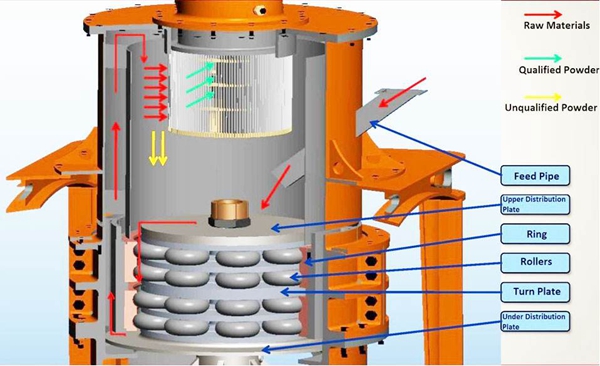

Working Principle of micro powder mill

The main bearing and each dial are driven by electromotor of main machine through reducer, and numbers of rollers, which are rolling in the ring, are driven by dial through plunger. After being crushed by Hammer crusher, big materials become smaller and are sent to storage hopper by elevator and further sent to the middle of first dial evenly by the electromagnetic vibrating feeder and feeding pipe. The materials will be driven to the edge of dial under centrifugal force and fall down into the ring, being crushed and grinded by roller, and become powder after production of three rings. The high pressure centrifugal blower will inhale air from outside and blow the crushed materials to classifier. The rotating turbo in the powder concentrator will make the coarse materials return to the mill for re-grounding, while the fineness will be mixed with the air and goes into the cyclone and be discharged in the discharge bin, which is located at the bottom of it. The air, which mixed with very little fineness, will be purified by impulse duster and discharged by blower and muffler.

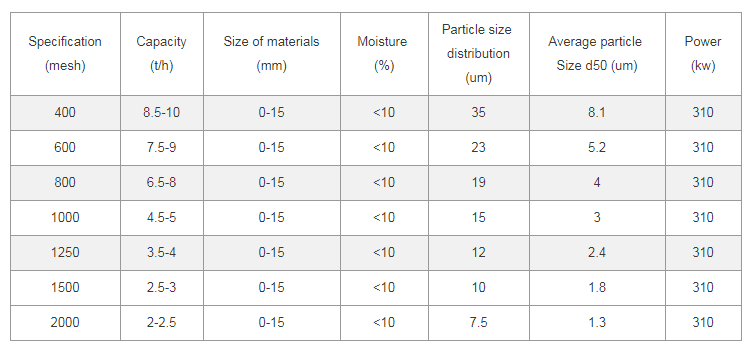

Techinical data of micro powder mill

Customer Service

Testing

If ore sample is provided by customers, we may do free spectrum or other testing. The testing reported is conducted by Mineral Prospecting Institute, and ranks the top in China.

Reagent Recipe

According to requirements for final products, we may provide free reagent ratio and dosage to customers.

Workflow

After knowing detailed information from customers, our technicians will provide the workflow and configuration for free.

Local Design

Our technicians will provide local design, layout, and tailing design for free after knowing detailed area of customers.

Guidance

Our engineer may provide 10 day’s training and guidance for free if necessary (including operation of machines, working notes and maintenance).